Injection molding is the most widely used processing technique for thermoplastics (also called plastic in English) A wide variety of plastic parts are manufactured using injection molding.and is particularly at higher volume production. Although the word “higher” implies that other processing techniques, such as Rapid prototyping; 3D printing, rotary injection molding and CNC machining, are better suited for lower production volumes.

It

depends on more factors , such as part size, complexity of the geometry application. The cost of raw plastic material (granulate ) The injection molding

process requires the clamp force of an injection molding machine, and a plastic mold with hot runner system the material loss even practically.

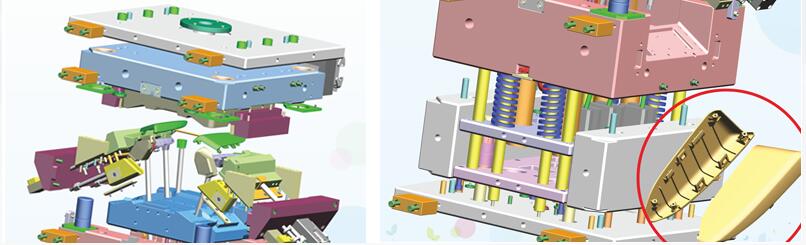

AMSL Tooling specializes in plastic injection, insert molding, technical molding; custom injection molding and over-molding of a wide range of plastics, as well as being experts in working with elastomer resins. This vast knowledge base allows us to assist customer make materials selection also we have the capability to offer a complete solution for client's manufacturing needs. From prototype tool to high volume production tool, and other value added services, such as parts sourcing, as well as complete product development, engineering, CNC milling /lathe parts secondary process; printing; painting; welding and parts assembly.

At AMSL Our 23 sets Haitian molding press with clamping force ranging from 45 tons to 600 tons able to meet your small orders or mass production needs. no matter hundreds of part or over millions parts, we are strict to follow our quality policy, processing full inspection or random check agreed with customer.

Would you like

to know more about the plastic injection molding of your product?

Our engineers are happy to tell

you how we can produce your product efficiently and with high-quality injection

molding. Please contact us for more

information.