Welcome To AMSL Tooling - Plastic Injection Mold Manufacturer:

Your Total-Solution Provider For Injection Molded Parts

AMSL Tooling is a Leading manufacturer of all types of injection moulds and plastic injection molding, AMSL provide you quality tooling with competitive price at short lead time. We can offer you complete solutions for your tight tolerance plastic components.

Our History

From April 2011, we start Export molds to the oversea customer and at the meantime we registered

ASIA MANUFACTURING SOLUTIONS (HK) LIMITED to provide better and more Tooling Services to the worldwide customers.

Year 2014, we purchased 1

set DAHLIH DM-2216 and OMIRON ST1800 EDM CNC for fabricate large molds to meet the clients requirements 2016, we increased our business, purchased 1 set 320T Haitian molding press and 1set 600T Haitian molding

press, at the same time we purchased ST750CNC-EDM Double spark EDM.

We are small or middle sized Tooling Shop, accumulated rich experience in Fabricating high quality injection molds; die casting tool; CNC part machining ; precision component making and mass production for Plastic injection moldings in the field of Automotive; Medical Device; Household appliance; Packaging; Crate; Industry; Marine Product; Aerospace; Defence; Farming and Garden etc...

We are aim to be the most competitive tool maker at maximum tool life with zero defect parts. No matter both large

or small projects, we work closely with our clients to turn their ideas into quality parts.

AMSL Tooling is located in the south part of China,Guangdong Province. our top management start mold making since 1998, make molds for toys and electronic parts development mainly serve mainland customer. our factory covers 8000 square meters, with over 100 highly trained and experienced employees.

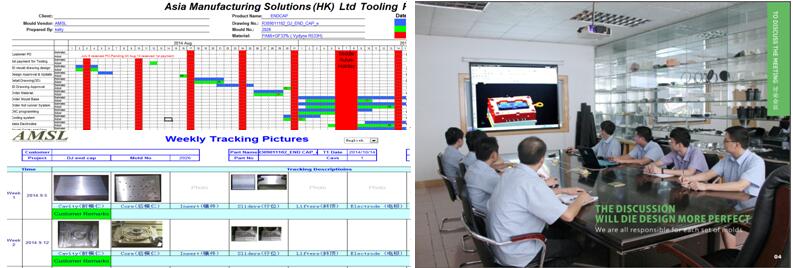

Project Management

- All of the RFQs will be handled by our sales team within 24 hours

- Your project manager will manage your project from design to delivery

- To increase work efficiency the Design for manufacturability (DFM) will be submitted for customer approval before mold design start

- New toolings meeting start after customer approval of 2D GA & 3D mold design

- Tooling schedule, regular weekly progress report and tracking pictures

- Quick response to the problem during manufacturing and solve it timely.

- Good communication channels between customer and our internal representatives.

- Quick feedback to the Engineering change notice (ECN)

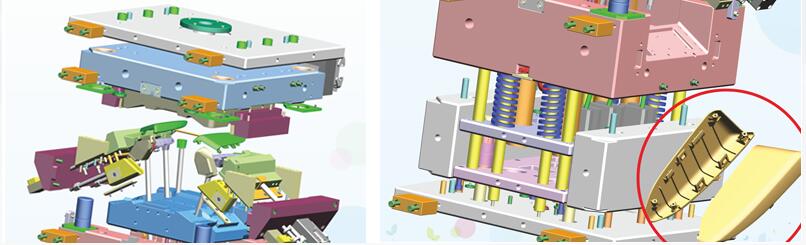

Mold Design

Our skilled designers are professional in UG;

Pro-E; Solidworks etc, we can assist our client turn the design concept to a

real plastic component With the advanced CAD /

- Variety of drawing formats

- Catia

- Pro-E

- Solidworks

- UG – Step ,IGS , x_t etc, STEP is much preferred.

Tooling Ability

We are capable to building your molds from SPI 101 level to SPI 105 level. Our advanced machinery allows us to build medium and large mould, the largest mold size we can make is : 3000*2000*1500(mm), and the weight can reach 15 Tonnage.

- At AMSL, before tooling start, we will assist our client for the part design consulting, raw material selection, and design for manufacturability ( DFM ), mold flow analysis and cost reduction strategies. We will ensure the cost of every dollars are much more valuable。

- At AMSL, our project engineer will be present at each tooling trials to ensure the tool works well, and make sure the moulds you received will last for many years to produce the quality molding parts that you are expected.

- At AMSL all of the moulds are tested , inspected and capability studied before it goes out of our facility.

- Our quality control team will check every step of the tooling process, from the incoming steel, mold base; raw material, standard components to electrodes, machining parts, hardness and surface checking to ensure they are all meet the requirements.

- We always aware about the deadlines for mold trials, Our team can get your moulds finished quickly and cost effectively.

- If needed we will assist our clients to choose the right sourcing depends on the price, quality required for your particular job

- AMSL also provide you other value added service, assist our customer to sourcing their parts or service from China, such as stamping parts; CNC machinings and copper nuts for insert mouldings etc...

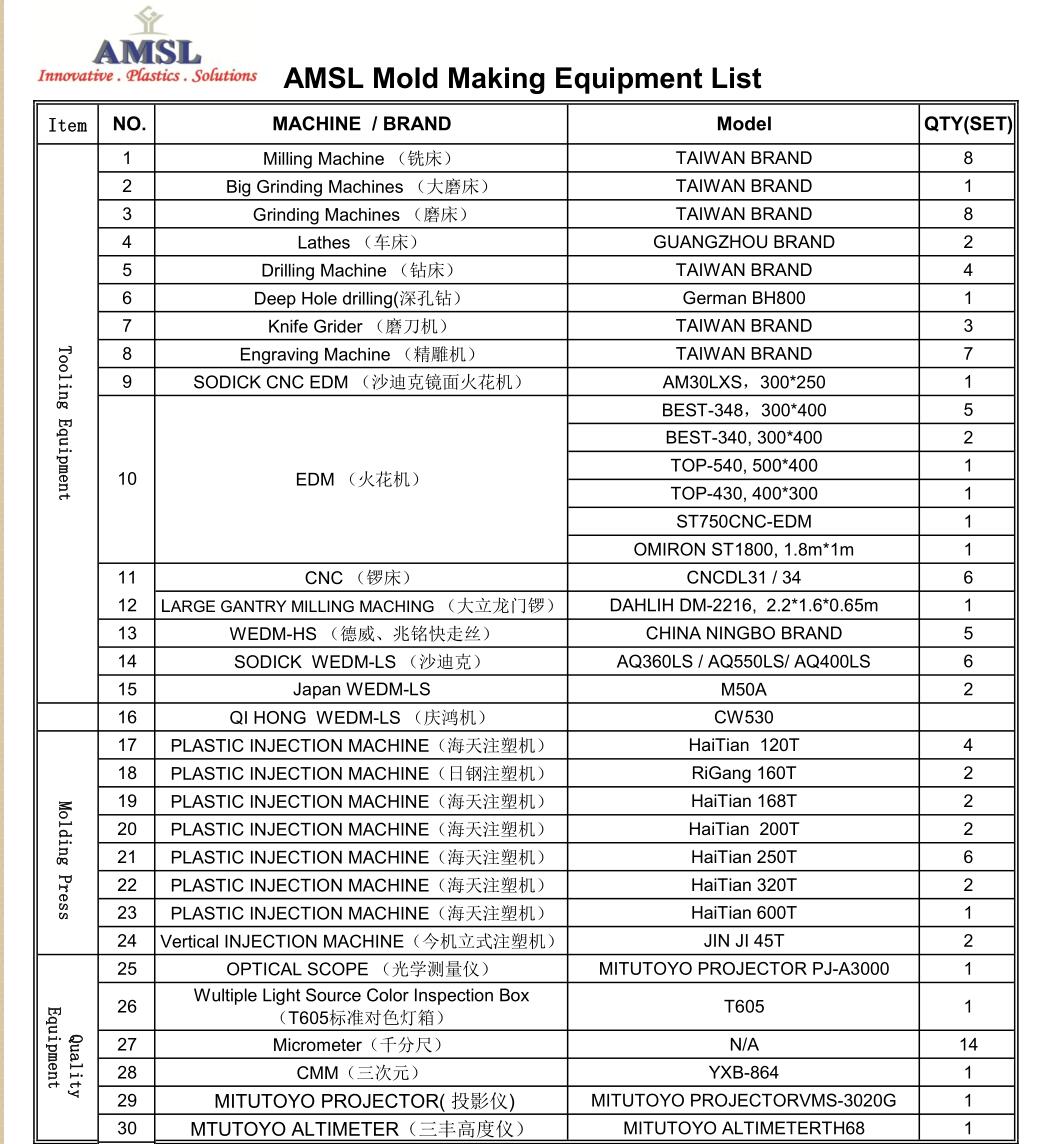

Equipment List